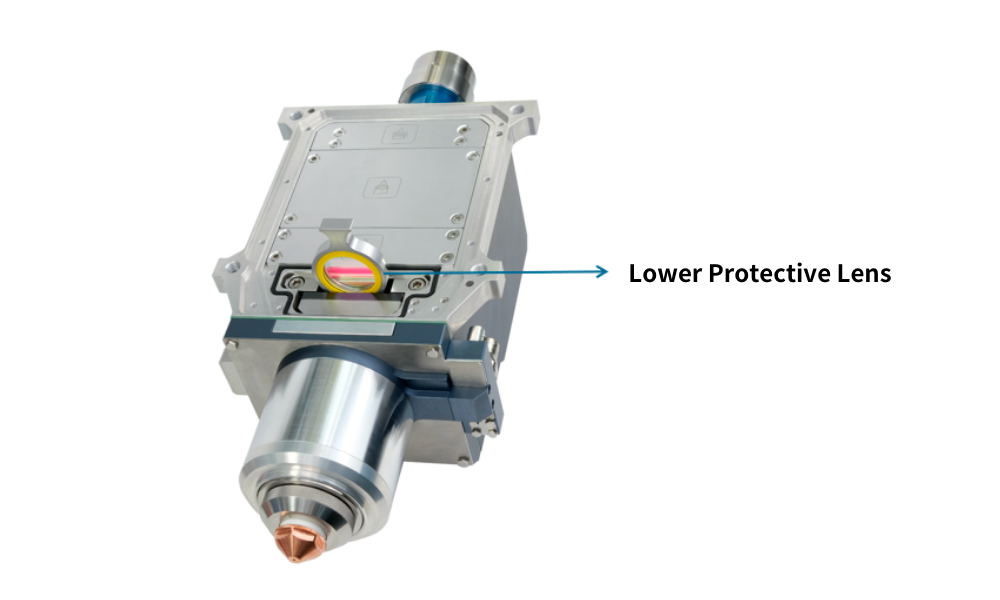

How to Choose the Lower Protective Lens of the Laser Cutting Head

In laser cutting equipment, the lower protective lens is a consumable part with a high replacement frequency. This guide will help you understand the importance of the lower protective lens, the consequences of improper selection, and how to choose the right one for your laser cutting head.

The Role of the Lower Protective Lens

The lower protective lens acts as a “double-sided fence” in the external optical path of the laser. Its primary functions are:

- Environmental Protection: Shields the internal optical components from dust, splashes, and other external contaminants.

- Laser Protection: Withstands high-power laser transmission internally.

- Gas Path Issues: Serves as the first line of defense in case of gas path problems, absorbing the initial impact and preventing damage to more expensive components.

Different manufacturers produce lower protective lenses with varying quality. A good lens must:

- Maintain the cleanliness of the internal optical path.

- Withstand high-power laser exposure.

- Ensure high laser transmittance.

These requirements demand strict standards for the substrate, processing, coating, and packaging of the lower protective lens.

Consequences of Improper Lens Selection

Using unqualified lower protective lenses can lead to several issues:

- Heat Absorption: Poor quality lenses absorb light and generate intense heat, causing focus drift and poor cutting performance.

- Lens Breakdown: Excessive heat can cause the lens to break down, potentially damaging the focus and alignment of the cutting head.

- High Maintenance Costs: Damaging high-value components can lead to maintenance costs amounting to 20-50% of the price of a new cutting head.

- Poor Coating: Inadequate coatings result in weak light transmittance and strong reflections, leading to return light passing through and potentially burning out the protective window at the output head end cap.

- Severe Damage: In extreme cases, the forward laser can be held back in the output head, causing the metal structure to be destroyed, water leakage, slag spraying, and irreversible damage to the cutting head.

How to Select the Lower Protective Lens

When selecting protective lenses, consider the following points:

- Substrate: Choose materials that are well-established in the industry.

- Manufacturer: Opt for manufacturers with high-power laser window and lens production qualifications.

- Coating: Ensure the coating is customized for the laser output wavelength to enhance permeability.

- Test Reports: Verify the protective lens through transmission wavelength reports, glossiness qualification reports, material type reports, weak absorption reports, coating adhesion reports, and size and shape reports.

Types of Protective Lenses to Avoid

Avoid the following types of protective lenses:

- Exposed Substrate: Lenses with the coating removed, exposing the quartz substrate. These can be identified by the naked eye.

- Poor Coating Quality: Lenses with uneven transmittance and high reflection areas, which can only be detected with professional instruments.

- Foreign Matter or Bubbles: Lenses with foreign matter or air bubbles between the film layer and substrate, which are prone to burning out under high power.

- Poor Finish: Lenses with poor finish have a shorter lifespan and are less durable.

Conclusion

Selecting the correct lower protective lens for your laser cutting head is crucial for maintaining high cutting quality, protecting internal components, and minimizing maintenance costs. By following these guidelines and choosing reputable manufacturers, you can ensure the longevity and efficiency of your laser cutting equipment.